|

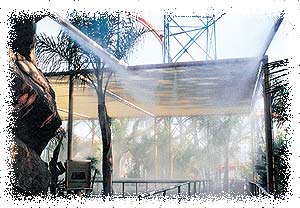

Water misting systems have proven to be more effective than conventional methods for cooling outdoor locations like a patio, green house, waiting line, or dining area. A mist fan system can increase productivity and employee morale in hot indoor or outdoor industrial working conditions. The concept incorporates water and heat to provide cooling through "flash evaporation". Specially designed mist nozzles operate under high pressure to produce tiny water droplets reducing the surrounding air temperature by as much as 20 F; 25 F with a fan. Our custom stainless steel mistline provides cooling to the area from our high pressure pump assembly. When combined with mist nozzles, this mist system can achieve maximum cooling without wetting or residual moisture. Mister systems can also provide a dynamic visual effect to any home, patio, or commercial location. Rapid Cool offers one of the largest selections of mister equipment, fans, and components on the market today for home or commercial use. Whether it is one of our portable misting fans to a complete misting system, Rapid Cool can handle most any indoor or outdoor home, patio, green house, industrial, or commercial application. of mister equipment, fans, and components on the market today for home or commercial use. Whether it is one of our portable misting fans to a complete misting system, Rapid Cool can handle most any indoor or outdoor home, patio, green house, industrial, or commercial application.

- Stainless Steel Mistline

- Powder Coated Enclosures

- Low Water Safety

- External Filter Location

- Stainless Steel Mist Rings for Fans

- Systems up to 3000 psi

|

- Anti-Drip Misting Nozzles

- Auto Drain

- Multi Station Capabilities

- Stainless Steel & Brass Mister Nozzles

- Thermostat Controlled

- Hi-Capacity Mister Pumps

|

Powered by www.impowerthemes.com

|